|

|

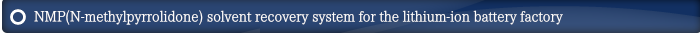

The system which gets condensed in the cooling after

continuously concentrating NMP which is used at the

lithium-ion battery factory and is recovered.

|

|

|

Ⅰ.There is little contamination in recovered and

the NMP and the degree of equal to or less than 1 wt%

of the expectation value.

Ⅱ.It combines with the distillation unit and the

proposal of the proposal of the high purity NMP recovery

system is possible.

Ⅲ.The environment measure ,CSR can be contributed

to all together with the economic effect in reusing

recovered NMP.

Ⅳ.The regeneration air temperature of the concentrator

is 140℃ and it is possible to use general factory steam

pressure 0.4MpaG.

|

|

|

●When number 10 ppm(vol) of solvent concentration

in the production process entrance are permissible ,it

combines and it builds a circulation system and zero

release into the atmosphere of the dehumidifier-system

becomes possible.

|

↑Please refer to enlarge↑

|

|

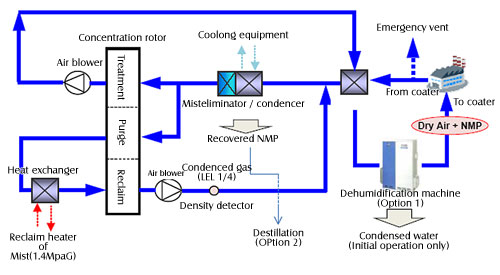

●It combines our distillation unit and it recover

high purity MWP and it gets to do can with the inside

of the hall recycling.

|

↑Please refer to enlarge↑

In organic solvent recovery ,it links

up with Environmental Partnership corporation

and it tackles the recycling processing of a industrial

waste.

|

|

|