|

|

it developed acid treatment equipment as the purpose

to reduce the acid value of the solvent (ethyl acetate)

which was recovered at the recovery equipment

|

|

|

It reduces an acid value in treatment agent’s absorbing

acetic acid in the ethyl acetate and removing a settled

treatment agent.

|

|

↑Please refer to enlarge↑

|

↑Please refer to enlarge↑

|

|

|

|

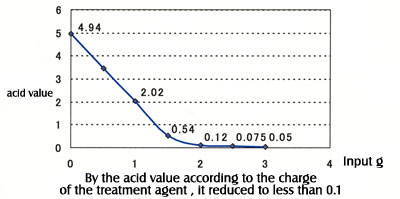

It is result of adding acetic acid and water to

solution of 100% of ethyl acetates ,investing a treatment

agent in 200ml of solution of acid value 4.94, 1% of

moisture and measuring an acid value after stirring

for 5 minutes

|

|

|

|

↑Please refer to enlarge↑

|

|

|

The Implementation April 7,2010

|

throughput

|

operation time

|

before acid treatment

|

after acid treatment

|

Sample:1

|

acid value(mgKOH/g)

|

200L

|

|

2.587

|

0.6857

|

|

degree of moisture(wt%)

|

2.831

|

2.741

|

Sample:2

|

acid value(mgKOH/g)

|

200L

|

|

2.026

|

0.468

|

|

degree of moisture(wt%)

|

2.852

|

2.67

|

Sample:3

|

acid value(mgKOH/g)

|

200L

|

|

2.431

|

0.062

|

|

degree of moisture(wt%)

|

2.95

|

2.615

|

|

|

It is the result of the bringing in test in printing

company which took cooperation.

It processed the recovery liquid of about 3 acid

values and it confirmed reduction to equal to or less

than 0.05 acid values and we received report that was

not a problem as a result of the reuse with the dry

laminating-machine .

Also ,there was an effect that the degree of moisture

after processing gets for about 25% to be low since

before processing ,too.

|

|

|

●It manufactures according to the request the customer.

●It is possible to examine by the processing experiment

or the test machine bringing in

the company,if it is possible to take your recovery

liquid sample too.

●The development test of the diversion into the

other solvent and the water-treatment agent too,is in

progress.

●Only the necessary quantity can be processed.

●It is possible for the acid value to reduce in

few various cost.

●The maintenance ,too,is easy in the simple operation.

|

In organic solvent recovery

,it links up with Environmental Partnership corporation

and it tackles the recycling processing of a industrial

waste.

|

|

|